Offering Singular Machine Components and Assemblies

PMR Global Machine and Tool

Is a job shop specializing in CNC machining for the Oil field, Aerospace, Defense and other commercial industries. We have considerable machining gravitas with a lofty 100+ years of experience.

PMR Global Credentials

- ISO 9001 : 2015 - certification

- AS9100D - certification

- Exostar - registered

SCHEDULE A TOUR OF OUR WORLD CLASS MACHINES AND CAPABILITIES

HAAS TL-2 Lathe 2 0” Dia. X 48.0” Length

HAAS ST-10 Lathe 2 75” Dia. X 8.75” Length

HAAS ST-20 Lathe 2 0” Dia. X 10.0” Length

HAAS ST-30 Lathe 4 0” Dia. X 16.0” Length

HAAS VF-3 Mill (Trunnion option) 5 0” X 15.0” X 20.0”

HASS VF-6 Mill (Trunnion option) 5 0” X 27.0” X 25.0”

HASS ST-40 Lathe 2 5” X 32.0” Length

HASS ST-40 Lathe 2 5” X 32.0” Length

Mazak HyperQuadrex 150 Multi-Axis 9 375” Dia. X 20.0 Length

Mazak HyperQuadrex 250 Multi-Axis 9 125” Dia. X 20.0 Length

Mazak VCL-T100 Laser Tube Cutting/Flat Sheet 4

4” Dia. Round X 24” Length X .250” Thick

3” Square X 24’ Length X 2.50” Thick

20" X 24" Sheet (Max. 35 lbs. or .250" Max Thickness)

Mazak VC-500 Multi-Axis 5 69” X 19.69” X 12.00”

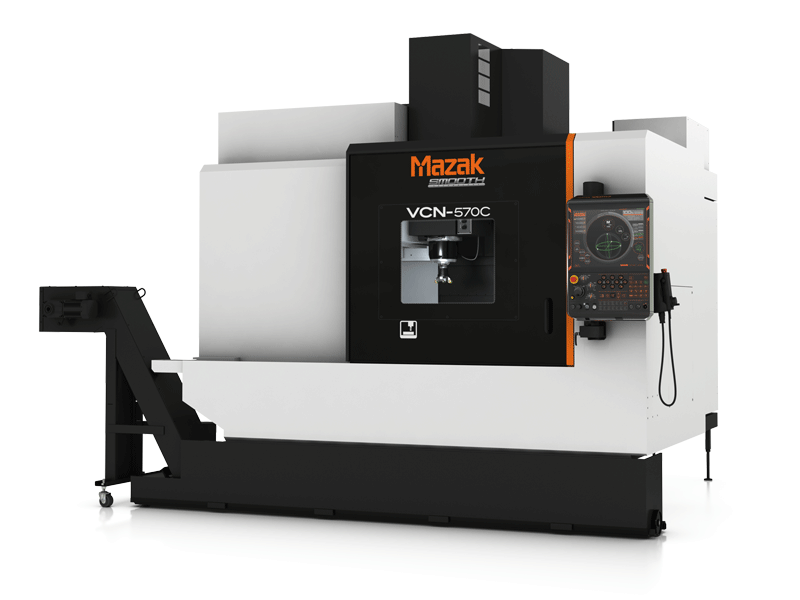

Mazak VCN570C Mill 4 0” X 22.00” X 20.”

Yama Seiki SW-20 Swiss Lathe

SW-20 series offers more flexabile operations such as turning, milling and cross drilling. From a different combination of power systems, main-spindle, sub-spindle, front-end tool, rear-end tool, C-axis and driven tools which means the workpiece can be finished at one time and also allows two operatons to be machined simultaneously. 1.63HP high power driven motor and a maximum of up to 10 driven tools which can meet any machining task

Mori Seiki NL1500 SMC

MAXIEM1530 JetMachining Center

- Cutting envelope of 10' 0" x 5' 2" (3.04 m x 1.57 m)

- ±0.003" (±0.076 mm) linear position accuracy

Stoelting Parts Washer

- Full-service CNC and multi-axis machining

- Completed parts per print, from material acquisition to outside processes such as coating, heat treat, specialty threads, etc.

- Singular components or assemblies

- Optimized setups to reduce cost and machining time

- Utilization of best in class cutting tools to optimize processes and increase throughput

- Titanium specialists

- Exotics such as Inconel, Ampcoloy, MP35, Silicone Iron

- Plastics and composites including Delrin, Isoplast or Kydex, Torlon and more

- Aluminum 6061-T6 and 2024

- All steel including 41xx series

- All series Stainless Steel

- Copper, Brass and other mainstream metals

- Castings and Forgings